MiniFactory Ultra 2 – Industrial 3D Printing

Specialised in industrial 3D printing of ultra polymers, miniFactory has been developing 3D printers for a number of highly demanding areas of the market.

With their know-how, experience and years of development, they have cutting-edge industrial solutions that include many practical extensions, such as advanced software for production monitoring, automatic recognition after finishing, quality assurance, among others.

The miniFactory ULTRA 2 is one of the brand’s latest models and comes with new features and high performance in industrial 3D printing.

Superlative of performance

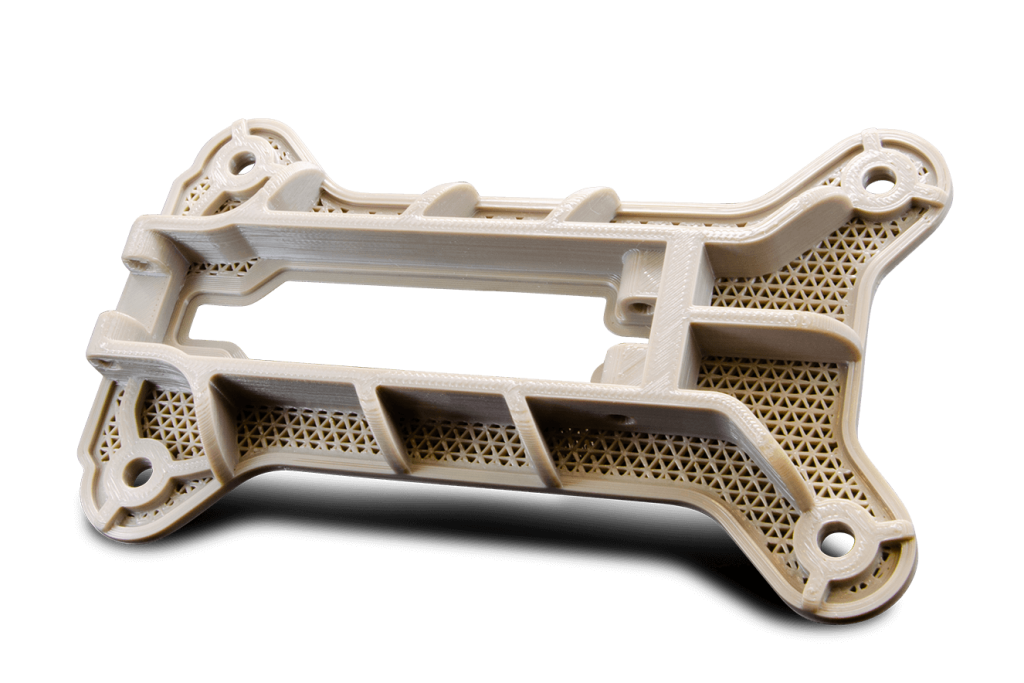

Ultra 2 is the perfect solution when you want a 3D printer with maximum performance and versatility.

Ultra 2’s advanced 250C heated chamber not only unlocks the ability to utilize materials like PEEK, PEKK, ULTEM1010, PPSU, PSU, and TPI, but it also empowers professionals in R&D to push boundaries.

With Ultra 2, you’re not just investing in a 3D printer; you’re investing in limitless possibilities.

New features. Made for value making.

Faster

Improved technical solutions together with software optimisations enables increased output with well known minifactory quality.

Stronger

Smart triple sensored heated chamber and optimised airflow ensure precise temperature management for stronger parts.

Smarter

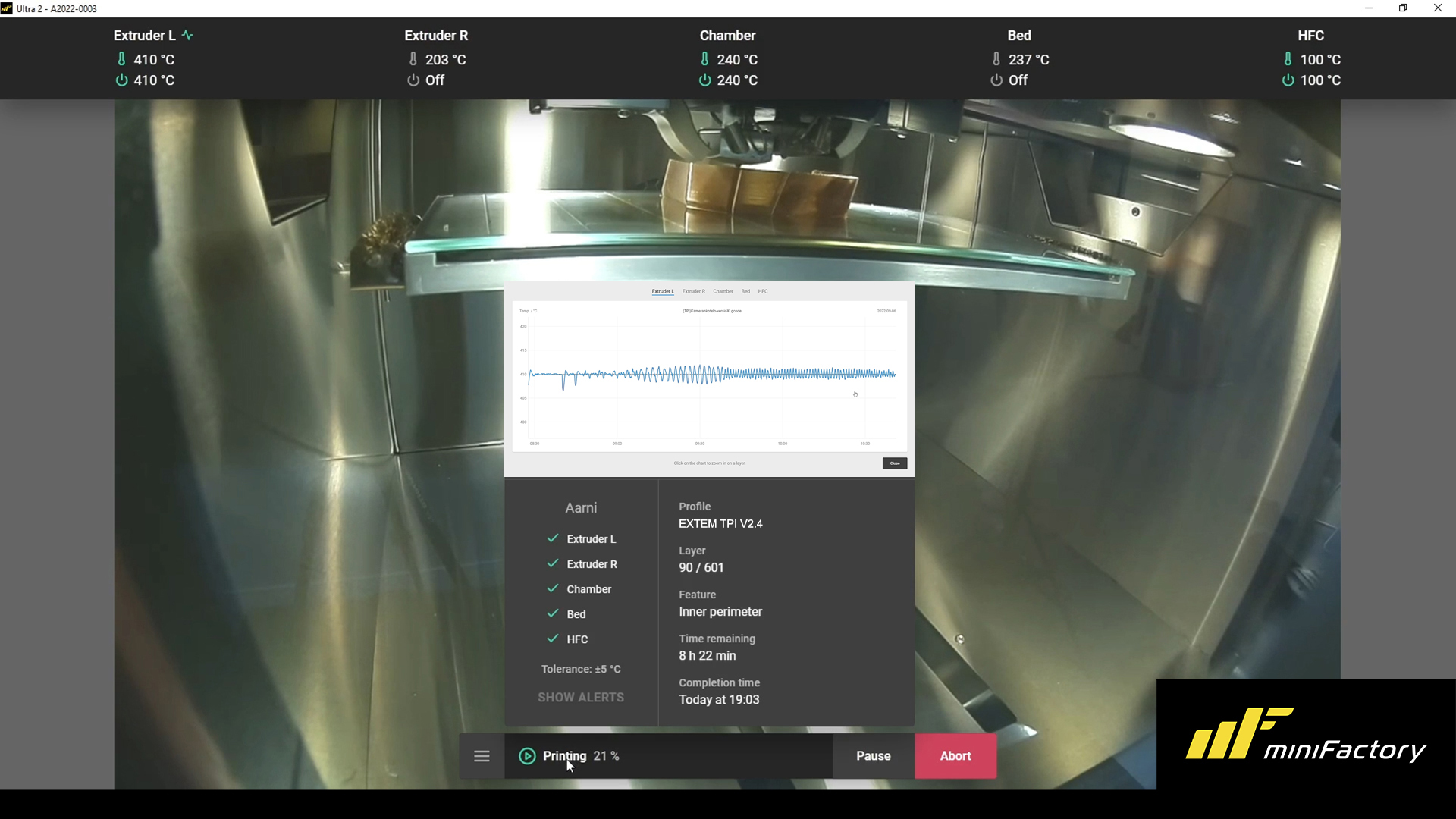

Real time quality assurance technology together with automatic production supervision ensure the high quality manufacturing.

Smoother

Usability due to simplified user interface equipped with remote control lets you control the printer anywhere. Industry 4.0 compatible system.

Open material system

MiniFactory material validation program enables fast integration of new materials.

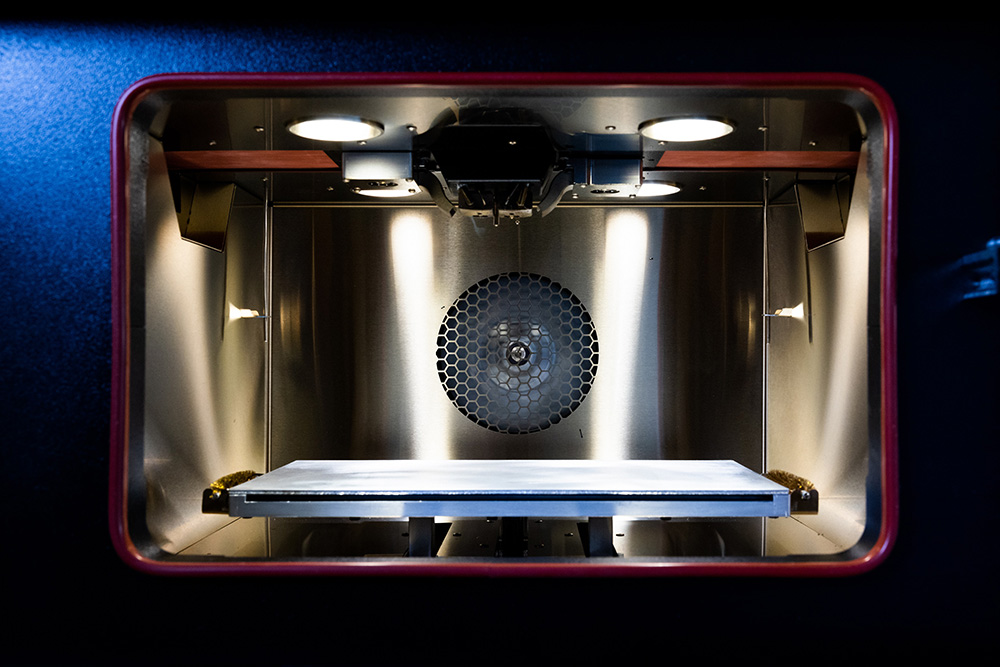

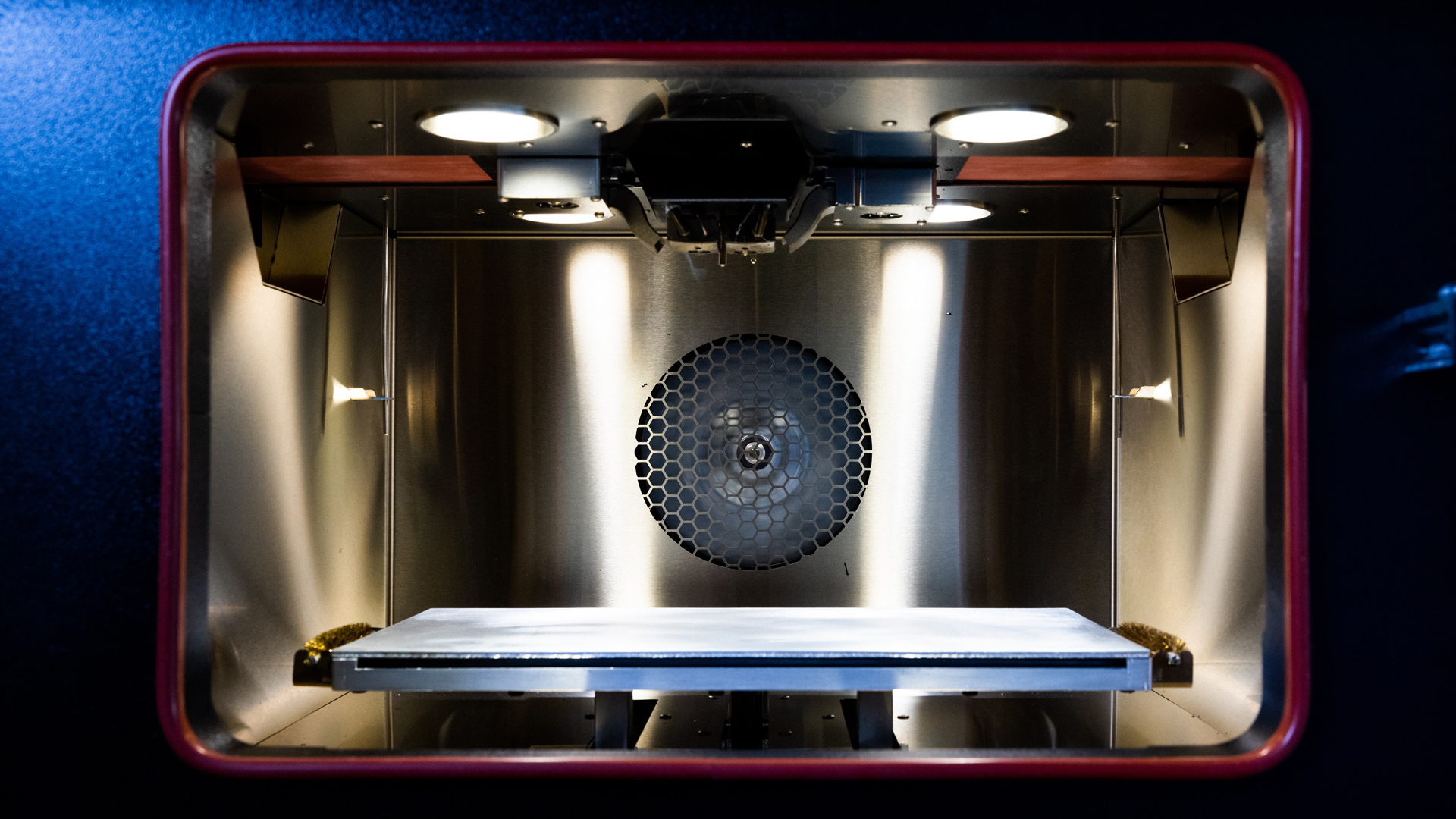

250°c Smart Heated Chamber

Unlocks the widest material range on the market and ensure the extreme stability of the printed part.

Integrated annealing system

Set the desired annealing cycle and increase the crystallinity of 3D printed PEEK or PEKK parts.

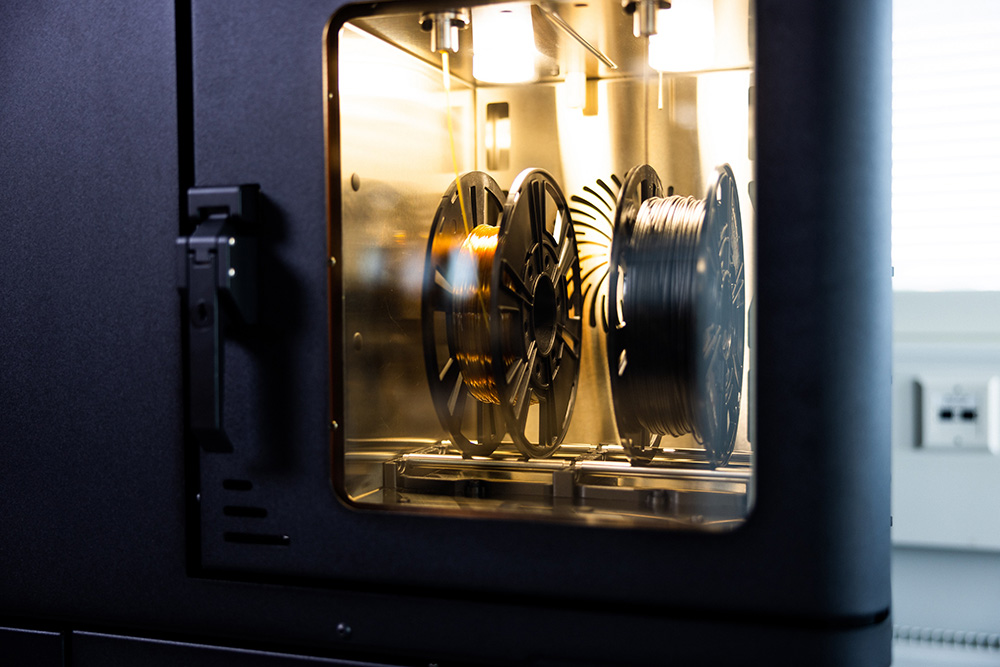

Active material drying chamber

Ensures the optimal humidity control for filaments to reach the best printing.

Quality assurance technology

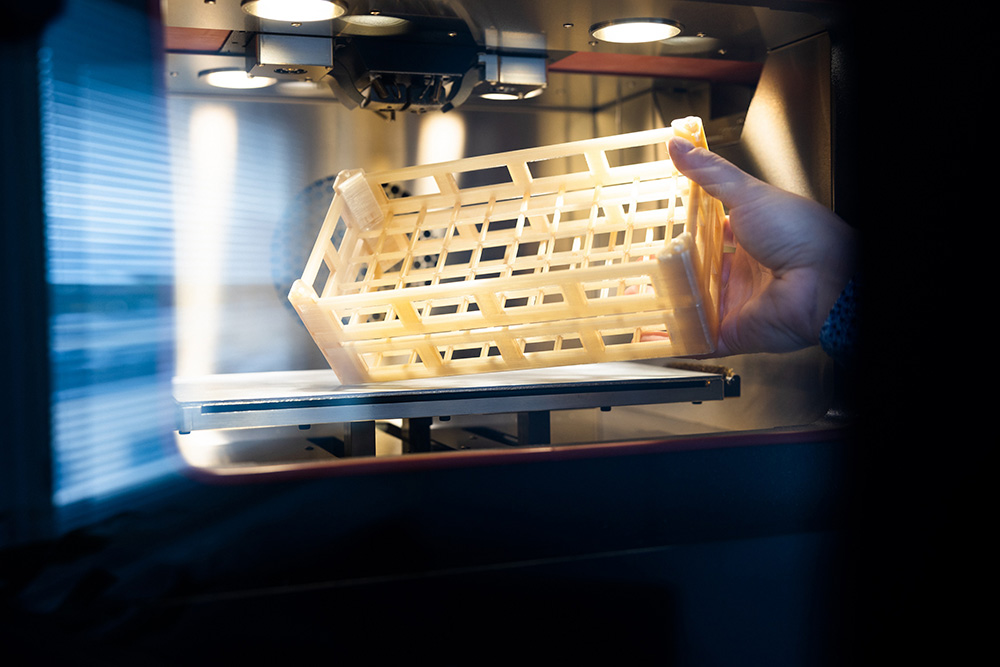

Layer-by-layer inspection of the printed part ensure that the process has been completed as desired.

Servo driven technology

High-end servo technology makes Ultra one of the most accurate FFF printing systems available.

Fast preparation time

It takes less than 30 minutes to heat the printing chamber at 220°C and start printing.

Smart maintenance intervals

Automatic recommendations quide you to keep your system in the perfect condition.

Technical Specifications

| BUILD VOLUME | 330 x 180 x 180mm |

| EXTRUDERS | 2 EXTRUDERS (MAIN MATERIAL + SUPPORT MATERIAL) |

| TEMPERATURES | BUILD CHAMBER 250C, BED 250C, NOZZLE 480C |

| MATERIALS | TPI, PPSU, PSU, PPS, ULTEM1010, ULTEM9085, PEEK, PEKK, PAEK, PACF, ABS, ASA, PEKK-A, PVDF and many more. |

| BUILD PLATFORM | INTERNAL VACUUM SYSTEM |

| LEVELING | FULLY AUTOMATIC CALIBRATION |

| UI | 10” TOUCH SCREEN |

| SAFETY | ACTIVATED CARBON FILTERING |

| MATERIAL DRYING & ANNEALING | INTEGRATED |

Three Layer Quality Assurance

Remote control with live feed

Production supervision

Layer-by-layer inspection

Contact Us

For more information on MiniFactory equipment, please contact us